Our 2018 DPPM Results Are In!

Defective parts per million (DPPM) is a term commonly used in manufacturing to quantify a defect rate. Basically, if you produced a million parts, how many of those would be defective? To calculate DPPM, you take the number of defects produced over a period of time, divide it by the total number of parts produced in the same time period, and then multiply by one million. That’s right. One million.

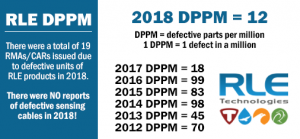

Our 2018 DPPM results are in. And the number is really impressive.

It’s 12.

That’s right – twelve. 12 DPPM. For every million parts we produced in 2018, 12 were defective. That is .0012%.

That’s not just good or great. It’s amazing and fantastic.

And it’s a testament to the focused, dedicated work we see from every employee every day at RLE.

What impacts DPPM? First and foremost, the number of defects reported. This number comes from our Return Materials Authorizations (RMA) and Corrective Action data. Each product defect is counted individually (service or process errors do not count). The number of products produced also impacts the DPPM. The larger the number of parts produced, the lower the DPPM number.

We can minimize the number of defects in a variety of ways, starting with our vendors. Having vendors that supply defect-free materials is critical. We constantly test materials from our vendors and visit their facilities to ensure we’re receiving the quality materials we expect. Next, generating high quality assembly build books – and always following those build books! – and testing products accurately and consistently is imperative. We also know that routine inspection of raw materials and components, quick segregation of non-conforming or questionable products, and thoroughly troubleshooting issues also play a large role in ensuring the products we produce are defect-free.

Obviously, the lower the DPPM the better! Looking across all industries, parts that impact health and safety have much more stringent DPPM requirements than parts that are considered inexpensive or one-time use. At RLE, we strive for a low DPPM in order to minimize customer complaints and maximize product consistency and dependable performance. This supports our Quality Program and Mission Statement: We exist to prevent disasters, preserve our clients’ reputation, and provide peace of mind.

Our 2018 DPPM of 12 is something we are very proud of. The RLE Team is very committed to ensuring our products perform for our customers as intended and that shows in our DPPM results. When we say our product reliability is second to none, that’s not just talk. We have the metrics to back it up.

Our 2018 DPPM of 12 is something we are very proud of. The RLE Team is very committed to ensuring our products perform for our customers as intended and that shows in our DPPM results. When we say our product reliability is second to none, that’s not just talk. We have the metrics to back it up.

Leave a Reply