Press Releases

RLE Technologies Announces Expansion of WiNG Product Line

The 865MHz Frequency Builds On The Success Of The 900MHz, And 868MHz Range For WiNG

Fort Collins, CO – February 28, 2024 — RLE Technologies, a leading provider of patented raised floors and containment, leak detection systems, and remote monitoring solutions for mission-critical facilities has expanded their WiNG wireless monitoring platform with the addition of the 865MHz frequency for the Indian market. The additional frequency builds on the success of the 900MHz, and 868MHz frequency range for the WiNG wireless solutions.

Our WiNG wireless monitoring products are already well-known in international markets. We’re excited to show our Indian customers how WiNG can be used to wirelessly monitor their unique facility needs.

“We are confident that the ease of deployment and long battery life of the WiNG system will be an asset to the Indian market,” says Brian Jones, RLE’s Engineering Manager. “Our goal with our products is to continue to bring peace of mind to critical facility operators worldwide.”

"Our monitoring solutions are competitively priced to help combat the higher cost of power in the Indian market compared to other countries where WiNG is well established," says Jennifer Thompson, the Director of Sales at RLE. "Investing in reliable, advanced technologies such as RLE’s WiNG environmental temperature and humidity monitoring solutions helps manage and reduce costs associated with running a data center while improving its efficiency."

WiNG managers, temperature and humidity sensors, and range extenders in the 865MHz frequency are now available for order.

About RLE Technologies

RLE Technologies is the global provider of Triad raised floors, grommets, and containment products, SeaHawk leak detection, Falcon facility monitoring solutions, and Raptor system integration products. Since 1984, our wired and wireless monitoring systems have provided peace of mind for facility stakeholders, and over 20 million feet of our patented leak detection cable is installed in facilities worldwide.

Additional information can be found at https://www.rletech.com

CONTACT:

Ashley Grisel

Marketing Manager, RLE Technologies

[email protected]

800-518-1519

###

RLE Technologies Introduces Wi-Fi Carbon Dioxide Sensor

Detect Changes in CO2 Levels Over Large Areas Through Preexisting Wi-Fi Networks

Fort Collins, CO – April 19, 2022 — RLE Technologies, a leading provider of patented raised floors and containment, web-based monitoring solutions, and leak detection systems for mission-critical facilities, has added the WIFI-CO2 sensor to their popular line of wireless monitoring products. The WIFI-CO2 monitors three critical facility metrics: carbon dioxide, temperature, and humidity.

“Facilities have eagerly adopted Wi-Fi sensors,” says Tom Metzinger, RLE’s Vice President of Sales. “These sensors communicate on an existing Wi-Fi network, so they quickly enhance facility oversight. The WIFI-CO2 is an important addition to our product line because it supports several different verticals. IAQ is an increasingly critical issue for office spaces and schools, and monitoring CO2 is an important piece of any fresh air strategy. Prime CO2 levels are also pivotal to the growth, maturation, and yield of plants so we’re seeing gains in horticulture as well.”

“Designing our CO2 sensors has been a fun project,” says Brian Jones, Firmware Engineer, RLE Technologies. “In order to develop the best sensor for our customers, I researched how CO2 affects different environments. For instance, when people are in an enclosed space, you want to drive down CO2 levels to help occupants be healthy and alert. We demonstrated that in our offices – we could see CO2 readings plummet and people felt fresher just by opening a door. But conversely in a horticulture environment, plants thrive in higher CO2 levels. It’s fascinating how an alarm condition for one customer can be an ideal range for another customer.”

RLE’s WIFI-CO2 wireless carbon dioxide sensor is in stock now and ready to ship.

About RLE Technologies

RLE Technologies is the global provider of Triad raised floors, grommets, and containment products, SeaHawk leak detection, Falcon facility monitoring solutions, and Raptor system integration products. Since 1984, our wired and wireless monitoring systems have provided peace of mind for facility stakeholders and over 20 million feet of our patented leak detection cable is installed in facilities worldwide.

Additional information can be found at https://www.rletech.com

CONTACT: Jennifer Peterson

Manager, Marketing and Communications, RLE Technologies

[email protected]

970-232-3930

###

RLE Technologies Names Tim Hirschenhofer Company President

Hirschenhofer Takes Reigns As Swanner, Raymond Jr. Retire

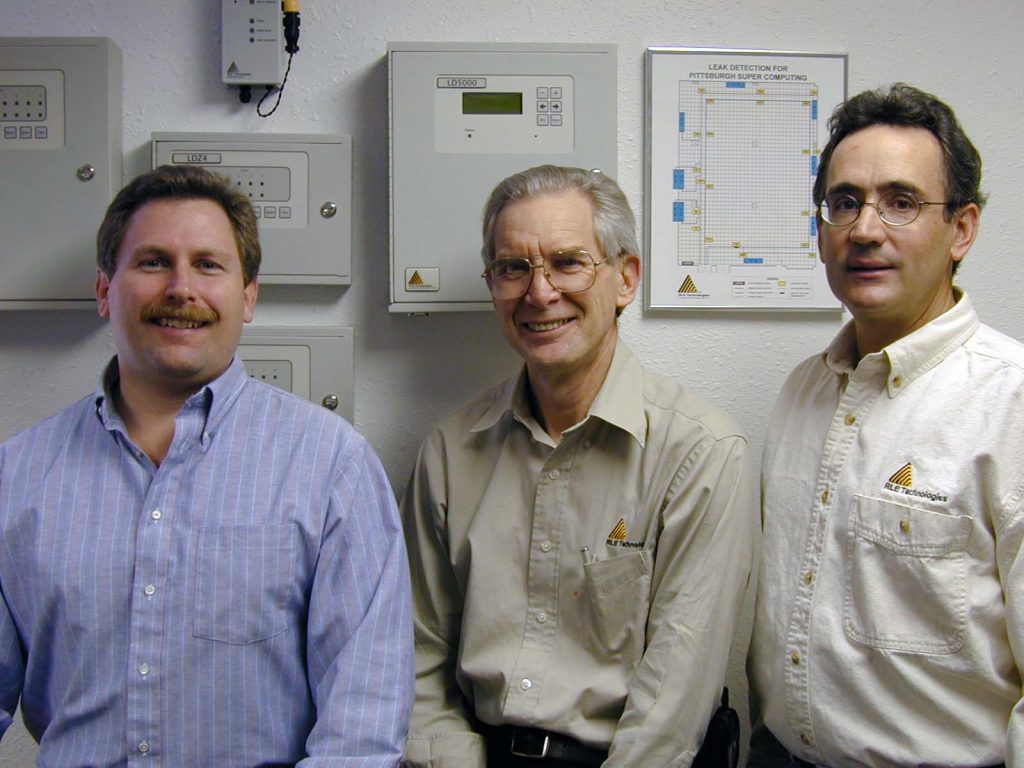

Fort Collins, CO – January 11, 2022 — RLE Technologies, a leading provider of patented raised floors and containment, web-based monitoring solutions, and leak detection systems for mission-critical facilities, announced management changes as Jeremy Swanner and Don Raymond Jr. retire and Tim Hirschenhofer is promoted to the role of President.

“Jeremy and I have long looked forward to our retirement.“ says Don Raymond Jr., Founder, RLE Technologies. “I’ve worked hard for 40 years to build a strong, innovative company that’s poised for enduring success. We are grateful to name Tim Hirschenhofer as RLE’s next President and are confident that his leadership and dedication will serve the company and RLE employees well for years to come.”

“Tim has been my friend for more than 20 years and has our full confidence and trust,” says Jeremy Swanner, Chairman of the Board, RLE Technologies. “Tim’s experience in our industry and knowledge of RLE products are second to none. He guided RLE through the Covid pandemic and subsequent supply chain disruptions with forethought and diligence. His efforts kept manufacturing operations running, orders shipping, and customer needs met during these unprecedented times.“

Hirschenhofer has worked for RLE for seven years, most recently serving as Senior Vice President of Operations. His experience in the semiconductor and data center industries, coupled with the breadth and depth of his RLE product knowledge, help him understand how to position RLE for future growth. He’s worked interdepartmentally at RLE to build trust, confidence, and camaraderie among RLE’s employees.

RLE employees added heartfelt messages for Swanner and Raymond Jr.:

It has been one of the greatest honors of my life to see the Company my Father, Grandfather, and Uncle founded grow over the span of my lifetime.

My Father is an amazing man, although he would never admit it, his innovation and brilliance made this Company what it is today. His kindness and generosity towards his family and employees can be seen throughout the culture at RLE. It has been a blessing to work alongside him for the last 12 years and it is hard to imagine working here without him. While his career for over 38 years has come to a close, I truly hope that he can look back at his time at RLE fondly and at the same time, look forward to the next chapter of his life.

- Rebecca Raymond Sutton

Don and Jeremy, I wish you good health, wealth and happiness in your retirement. May all of your future journeys be pleasurable. Thank you for your never ending kindness and support of my work after taking me on with the Triad acquisition. You always made me feel so welcome when I came to HQ and I will miss the hug we always exchanged at my arrival and departure times.

My best always, Jen Beliveau

Don - It has been a real pleasure working with you these past 4 and a half years. Thanks for all your valuable engineering lessons - you’ve taught me a lot. I really appreciated all the passion and engineering joy you would bring to all of our work here. I’ll be sure to call you up when it’s time to record the old-timey video of “What not to do with an RLE leak detection cable”.

Jeremy - I’ve really appreciated the way you’ve run the company and your open and honest communications. When friends and family would ask if I was concerned about how RLE would fare during 2020 I could honestly answer “No - Jeremy has a really good handle on everything. I’m sure we’ll get through it just fine.” It’s been excellent working with you, and I hope you have a great time in retirement! Let me know if you come across any good smoker recipes!

- Ryan Clemens

38 years ago Don Raymond, Don Raymond, Jr and Roy Lae founded RLE and Don, you are the last of the founders to leave. I sincerely thank you for your Entrepreneurship, the incredible products that you have developed over the years, and the jobs that you’ve provided. Best wishes to you and Jeremy!

- Cam Rogers

About RLE Technologies

RLE Technologies is the global provider of Triad raised floors, grommets, and containment products, SeaHawk leak detection, Falcon facility monitoring solutions, and Raptor system integration products. Since 1984, our wired and wireless monitoring systems have provided peace of mind for facility stakeholders and over 17 million feet of our patented leak detection cable is installed in facilities worldwide.

Additional information can be found at https://www.rletech.com

CONTACT: Jennifer Peterson

Manager, Marketing and Communications, RLE Technologies

[email protected]

970-232-3930

###

RLE Technologies Adds Wireless Carbon Dioxide Sensor to WiNG Product Line

Monitor CO2 Levels, Ensure Building Health, Meet Safety and Occupancy Requirements

Fort Collins, CO – July 27, 2021 — RLE Technologies, a leading provider of patented raised floors and containment, web-based monitoring solutions, and leak detection systems for mission-critical facilities, is improving the insight and oversight users have into the their buildings with the introduction of the WiNG-CO2 wireless carbon dioxide sensor.

The WiNG-CO2 sensor monitors three critical facility metrics: carbon dioxide, temperature, and humidity. It reports these values to a WiNG-MGR or BMS-WiNG, and alerts can be delivered immediately to recipients via email and a web user interface. Alerts can also be pushed to a BMS for a single pane of glass monitoring solution.

“CO2 has quickly become a critical metric for many of our customers and the data provided by the WiNG-CO2 is accurate, timely, and actionable,” says Brian Jones, a Firmware Engineer at RLE and the designer of the WiNG-CO2. “This sensor is a versatile solution that you can quickly add to any new or existing WiNG system. Monitoring air circulation helps track building occupancy for the comfort and safety of your building’s occupants, and it also allows you to monitor air handling equipment and quickly detect impeded airflow, stalled fans, leaks, blockages, and clogged filters.”

“The sensor is built around really robust technology,” continues Jones. “The CO2 module we use in the WiNG-CO2 sensor is self-calibrating, zero maintenance, has a broad range and excellent accuracy, plus a 15-year CO2 sensor life expectancy.”

The WiNG-CO2 is available in both 900MHz and 868MHz configurations and a perfect fit for a variety of applications including:

- Tracking building air quality

- Monitoring HVAC systems

- Counting indoor human occupancy

- Monitoring horticulture facilities and greenhouses

RLE’s WiNG-CO2 wireless carbon dioxide sensor is in stock now and ready to ship.

About RLE Technologies

RLE Technologies is the global provider of Triad raised floors, grommets, and containment products, SeaHawk leak detection, Falcon facility monitoring solutions, and Raptor system integration products. Since 1984, our wired and wireless monitoring systems have provided peace of mind for facility stakeholders and over 17 million feet of our patented leak detection cable is installed in facilities worldwide.

Additional information can be found at https://www.rletech.com

CONTACT: Jennifer Peterson

Manager, Marketing and Communications, RLE Technologies

[email protected]

970-232-3930

###

RLE Technologies Expands Spot Detector Product Line

SD-RO2 Provides Local Alarm Notification with LED, Audible Alarm

Fort Collins, CO – July 20, 2021 — RLE Technologies, a leading provider of patented raised floors and containment, web-based monitoring solutions, and leak detection systems for mission-critical facilities, has expanded their spot detector line of products with the addition of the SD-RO2.

“The SD-RO1 is far and away our most popular spot detector,” says Don Raymond, RLE’s founder and CTO. “When you have product that reliably sells tens of thousands of parts a year, you know it’s a proven success. And then you start thinking about how you can branch out from that successful product and offer an expanded version that meets additional market needs and customer requests. We often have customers who purchase audible alarms or sirens to go with their leak detection. These upgrades make the SD-RO2 a very natural evolution of our spot detectors.”

The SD-RO2 builds on the success of the SD-RO1. The SD-RO2 detects leaks just like the SD-RO1: place it in a location where a leak is likely to occur, and the device will alert you to the presence of water or another liquid leak. The electronics are potted, so the unit can be almost completely submerged in water and still sends a leak alert. The following additions really set the SD-RO2 apart:

- The SD-RO2 has two relay outputs which allow alarms to be integrated into two separate BMS or DCiM systems.

- The SD-RO2 has LEDs and an audible alarm, so local staff immediately see and hear an alert when a leak is detected.

RLE’s SD-RO2 is in stock now and ready to ship.

About RLE Technologies

RLE Technologies is the global provider of Triad raised floors, grommets, and containment products, SeaHawk leak detection, Falcon facility monitoring solutions, and Raptor system integration products. Since 1984, our wired and wireless monitoring systems have provided peace of mind for facility stakeholders and over 17 million feet of our patented leak detection cable is installed in facilities worldwide.

Additional information can be found at https://www.rletech.com

###

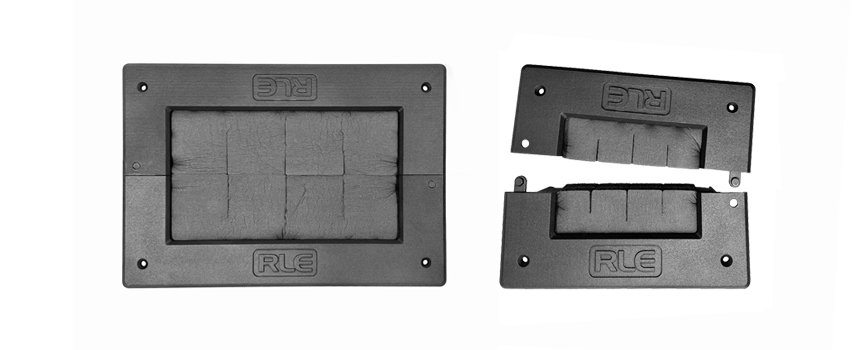

RLE Technologies Expands Raised Floor Grommet Product Line

New Dimensions, Sizes Help Customers Immediately Improve Airflow Efficiency

Fort Collins, CO – May 25, 2021 — RLE Technologies, a leading provider of patented raised floors and containment, web-based monitoring solutions, and leak detection systems for mission-critical facilities, is excited to expand their raised floor grommet product line.

RLE’s patent-pending foam grommets are now available in three additional sizes and shapes – 6” square and 6”x4” and 6”x9” rectangles – which quickly and easily allow customers to further improve airflow and efficiencies in their facilities.

“Our six inch round grommet has really been embraced by our customers,” says Jeremy Swanner, President, RLE Technologies. “They appreciate its price point, effectiveness, and ease of use. We are grateful that we could partner with our local Colorado manufacturing contacts to expand our grommet offerings and quickly bring three new products to market.”

The three new grommets share all the same advantages as the rest of RLE’s grommet product line:

- The patent-pending foam design seals better than brushes, so RLE’s grommets allow 50% less air leakage than the competitor’s grommets.

- The split design is easy to insert around any size cable bundle, in existing cutouts, or against a flat surface or wall, which allows RLE’s grommets to provide an immediate ROI for customers.

- RLE grommets can be purchased individually or in bundles - so whether you need one grommet or many grommets in a variety of shapes and sizes, RLE can meet your facility requirements.

About RLE Technologies

RLE Technologies is the global provider of Triad raised floors, grommets, and containment products, SeaHawk leak detection, Falcon facility monitoring solutions, and Raptor system integration products. Since 1984, our wired and wireless monitoring systems have provided peace of mind for facility stakeholders and over 17 million feet of our patented leak detection cable is installed in facilities worldwide.

Additional information can be found at https://www.rletech.com.

###

RLE Technologies Expands Wi-Fi Sensor Options

Now Monitor Refrigerators, Dryers, Heating and Cooling Ducts, and Fluid Leaks

Fort Collins, CO – March 10, 2021 — RLE Technologies, a leading provider of patented raised floors and containment, web-based monitoring solutions, and leak detection systems for mission-critical facilities, has added new sensing options to their popular Wi-Fi line of wireless monitoring products.

“Wi-Fi sensors provide so many advantages for our customers. Most data centers already have Wi-Fi infrastructure in place; RLE’s product line lets you drop in sensors wherever you need them to monitor conditions globally and centralize all that data into one oversight system,” says Ryan Clemens, RLE’s Director of Engineering.

Since its launch in 2019, the WIFI product line has been widely embraced by RLE’s customer base. With the global increase in facility monitoring, now is the ideal time to expand the sensor line:

- The WIFI-1WIRE couples a Wi-Fi wireless transmitter with a probe-style sensor on a 25’ leader cable to monitor temperature and humidity and provide a calculated dew point.

- The WIFI-LD pairs a Wi-Fi wireless transmitter with RLE’s patented leak detection cable or spot detectors to notify users of conductive fluid leaks before damage can occur.

“The biggest asset RLE’s wireless technology provides? It works,” says Michael Hadt, RLE’s Midwest Account Manager. “I’m often asked about the advantages of wireless monitoring. Ultimately the biggest advantage is streamlining efficiency for immediate deployment. Wi-Fi is great because it can provide coverage over very large areas through preexisting Wi-Fi networks. The sensor connectivity market is going to continue to multiply, especially now that monitoring spaces is more important than ever. RLE’s WIFI products enable visibility alarms and advanced controls strategies across enterprise networks across the globe, protecting data centers and all the other assets in any critical environment.”

RLE’s WIFI-1WIRE, WIFI-LD, and WIFI-TH sensors are in stock and available to ship today.

About RLE Technologies

RLE Technologies is the global provider of Triad raised floors, grommets, and containment products, SeaHawk leak detection, Falcon facility monitoring solutions, and Raptor system integration products. Since 1984, our wired and wireless monitoring systems have provided peace of mind for facility stakeholders and over 17 million feet of our patented leak detection cable is installed in facilities worldwide.

Additional information can be found at https://www.rletech.com

###

RLE Technologies Named

Most Promising Facilities Management Solution Provider

Fort Collins, CO – February 10, 2021 — RLE Technologies, a leading provider of patented raised floors and containment, web-based monitoring solutions, and leak detection systems for mission-critical facilities, has been named one of 2020’s Ten Most Promising Facilities Management Solution Providers by CIO Review magazine.

“RLE has worked hard over the past several years to develop and manufacture a robust product portfolio,” says Jeremy Swanner, President, RLE Technologies. “Our goal was to position ourselves as a one stop shop for facility managers. We wanted these busy professionals to know that they could source complete solutions from us, and to be confident that everything they purchased from RLE would meet our stringent quality standards. That we have been recognized within the industry for this accomplishment is both an honor and a testament to the hard work of our Engineering, Manufacturing, and Sales staffs.”

The award, presented by CIO Review magazine, acknowledges RLE’s dedication to and understanding of its customers, “The firm knows and understands well that it is their responsibility to make a facility manager’s job easy, less stressful, more informative, and insightful.” And that dedication is not just limited to a portion of RLE’s workforce. As CIO Review notes, “Every day at RLE, the employees come to work geared up to execute the company’s mission. RLE's integrated, agile, and cooperative workforce has been phenomenal in delivering quality products to its customers, even in the face of the COVID-19 pandemic that has struck the world. The clients, on their part, have unfailing faith in the services provided by RLE.”

Indeed, says CIO Review, “RLE has proven to be a company deserving of the title ‘Ten Most Promising Facilities Management Solution Providers 2020.’"

About RLE Technologies

RLE Technologies is the global provider of Triad raised floors, grommets, and containment products, SeaHawk leak detection, Falcon facility monitoring solutions, and Raptor system integration products. Since 1984, our wired and wireless monitoring systems have provided peace of mind for facility stakeholders and over 17 million feet of our patented leak detection cable is installed in facilities worldwide.

Additional information can be found at https://www.rletech.com

###

RLE Technologies Announces WiNG-MGR v2

Security, Integrated Mapping Enhance Wireless Monitoring Platform

Fort Collins, CO – November 19, 2020 — RLE Technologies, a leading provider of patented raised floors and containment, web-based monitoring solutions, and leak detection systems for mission-critical facilities, is excited to announce an update to their WiNG-MGR wireless sensor gateway device.

RLE has updated the WiNG-MGR, adding new features and security options to this already popular wireless sensor gateway device, including:

- TLS/HTTPS – Supports secure email services and TLS1.2 for encrypted communications and identity verification.

- Integrated Mapping – Create maps that help visualize data and quickly identify sensor locations. See sensor status at a glance with color coded labels based on alarm status.

- Fine Tune Sensor Readings – An offset adjustment is now included for T/TH sensors.

- Enhanced Logging Functionality – Now logs both temperature and humidity values every 5 minutes. Stores 30 days’ worth of data locally.

“The WiNG-MGR has been in the field for over three years now,” says Ryan Clemens, PE, RLE’s Senior Firmware Engineer. “In that time, we’ve had a lot of really great feedback and conversations with our customers. They love a lot of things about the platform – battery life, transmission range, integration capabilities. One critical feature customers were looking for was TLS/HTTPS support. We recognize that is very important to a lot of facilities, so it was the impetus for this update. The added processing power it required allowed us to add integrated mapping to the WiNG-MGR. The mapping is something I’m really excited about; it’s quick, easy, and intuitive. We’ve also added temperature offset, as well as enhanced logging. This is an update with some serious value. And because of our partnerships with local manufacturing companies, we were able to keep the MSRP for our WiNG-MGR v2 exactly the same as the v1 device.”

RLE’s WiNG-MGR v2 is in stock and ready to ship.

About RLE Technologies

RLE Technologies is the global provider of Triad raised floors, grommets, and containment products, SeaHawk leak detection, Falcon facility monitoring solutions, and Raptor system integration products. Since 1984, our wired and wireless monitoring systems have provided peace of mind for facility stakeholders and over 17 million feet of our patented leak detection cable is installed in facilities worldwide.

Additional information can be found at https://www.rletech.com

###

RLE Technologies Launches

Raised Floor Grommet Product Line

Products Block Air Better for Faster ROI

Fort Collins, CO – September 10, 2020 — RLE Technologies, a leading provider of patented raised floors and containment, web-based monitoring solutions, and leak detection systems for mission-critical facilities, is excited to add a line of grommets to their raised floor and containment product portfolio.

Fort Collins, CO – September 10, 2020 — RLE Technologies, a leading provider of patented raised floors and containment, web-based monitoring solutions, and leak detection systems for mission-critical facilities, is excited to add a line of grommets to their raised floor and containment product portfolio.

The launch of the grommets allows RLE to expand an already robust product category. RLE has quickly become a one stop shop for a facility’s raised floor, airflow, and custom containment needs.

“The grommet was a very natural evolution for us,” says Jeremy Swanner, President, RLE Technologies. “We saw a huge opportunity to fill a gap in the market – pun intended - and leverage our US supply chain to keep pricing competitive. That competitiveness also allows us to sell grommets singly or in bulk orders. Whether you want one grommet or twenty, we’d love to work with you.”

The product itself is a nod to simplicity in both design and innovation. Its patent-pending foam design seals better than brushes, so RLE’s grommets allow 50% less air leakage than the competitor’s grommets. The split design is easy to insert around any size cable bundle in existing cutouts, which allows RLE’s grommets to provide an immediate ROI for customers.

RLE’s 6 inch round foam grommet is in stock and ready to ship.

About RLE Technologies

RLE Technologies is the global provider of Triad raised floors, grommets, and containment products, SeaHawk leak detection, Falcon facility monitoring solutions, and Raptor system integration products. Since 1984, our wired and wireless monitoring systems have provided peace of mind for facility stakeholders and over 17 million feet of our patented leak detection cable is installed in facilities worldwide.

Additional information can be found at https://www.rletech.com

###

RLE Technologies Announces Hire of

Tom Metzinger, Vice President of Sales

Move Positions Company to Expand Sales in Existing and New Markets

Fort Collins, CO – July 13, 2020 — RLE Technologies, a leading provider of patented raised floors and containment, web-based monitoring solutions, and leak detection systems for mission-critical facilities, is excited to announce that Tom Metzinger has joined the company as RLE’s Vice President of Sales.

Fort Collins, CO – July 13, 2020 — RLE Technologies, a leading provider of patented raised floors and containment, web-based monitoring solutions, and leak detection systems for mission-critical facilities, is excited to announce that Tom Metzinger has joined the company as RLE’s Vice President of Sales.

“Tom has consistently driven results over a sales career spanning 30 years,” says Jeremy Swanner, President, RLE Technologies. “Through these leadership roles, Tom has gained extensive experience developing sales staff and growing teams, diversifying revenue streams, and increasing market penetration. We are excited that Tom has joined RLE and look forward to the positive impact he’ll have here.”

Tom’s background encompasses a growth of roles and responsibilities in sales and leadership positions, with a continuous focus on the growth of his technical skill set. As his roles in different industries grew, so did his technical knowledge in telecommunications, wireless technologies, voice and data deployments, technical instrumentation, and most recently, oil and gas. Throughout his career, Tom has leveraged his technical, interpersonal, and leadership skills to facilitate growth for both the companies he’s worked for and the personnel who have work on his teams.

“I’m excited to discover and develop new opportunities for RLE’s products, and to help our current customers learn how our complete suite of products can be leveraged effectively to meet their needs,” notes Metzinger. “I’ve always been focused on maximizing the potential of each company I’ve worked with and each team I’ve been a part of. RLE is widely recognized as a proven industry leader – I feel fortunate to be able to step into this role and build relationships grounded in a foundation of quality products, reliable solutions, and a customer-focused product development.”

About RLE Technologies

RLE Technologies is the global provider of Triad raised floor and containment products, SeaHawk leak detection, Falcon facility monitoring solutions, and Raptor system integration products. Since 1984, our wired and wireless monitoring systems have provided peace of mind for facility stakeholders and over 17 million feet of our patented leak detection cable is installed in facilities worldwide.

Additional information can be found at https://www.rletech.com

###

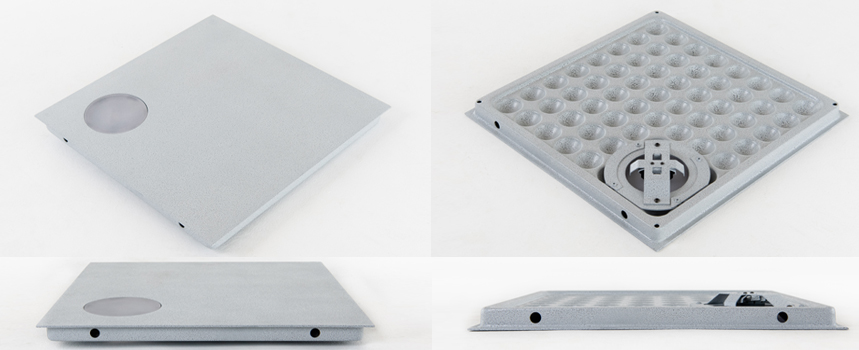

RLE Technologies Launches Floor Panel with Wireless Environmental Monitoring Capabilities

Fort Collins, CO – May 18, 2020 — RLE Technologies, a leading provider of patented raised floors and containment, web-based monitoring solutions, and leak detection systems for mission-critical facilities, is excited to introduce the RFM – a raised floor panel that securely houses one of RLE’s patented WiNG wireless monitoring sensors.

The launch of the RFM allows RLE to combine two of their most popular products, a solid steel floor panel and WiNG wireless sensors, to provide a solution that helps facilities seamlessly monitor conditions in an existing raised floor environment.

“WiNG has been such a popular product line for us,” says Jeremy Swanner, President, RLE Technologies. “As we developed a wider offering of wireless sensors, including differential pressure and airflow sensors, we started to have great conversations with our customers about how they’re deploying these products. Integrating a WiNG sensor with a raised floor panel was the next logical step to help us meet our customer’s evolving needs.”

Each RFM panel has a mounting bracket that secures a WiNG sensor to the bottom of the panel. This makes adding monitoring in an underfloor plenum space quick and easy.

“You don’t have to think about how you’re mounting sensors in tight quarters,” says James Schneider, RLE’s lead Mechanical Engineer. “A lot of our customers want to add a few more WiNG sensors to monitor that plenum space, and we’ve designed a flexible, durable solution that allows them to do just that. You simply lift out your existing raised floor panel and drop the RFM in its place.”

The RFM panel also brings another patent to RLE’s portfolio. A total of 35 patents is a testament to RLE’s commitment to innovation.

“We are always collaborating, always brainstorming, always innovating,” says Don Raymond, CTO and Founder, RLE Technologies. “This solution that leverages strengths from two of our product lines is a great example of a creative, customer-focused solution. As a company, we’re fortunate to have relationships with both our customers and our suppliers that help us understand the solutions our customers are looking for and bring new products to market quickly.”

RLE’s patent pending RFM panel is available with a gray flek or crystal white powder coat finish and an optional gray starlight laminate top sheet. The RFM is in stock and ready to ship.

About RLE Technologies

RLE Technologies is the global provider of Triad raised floor and containment products, SeaHawk leak detection, Falcon facility monitoring solutions, and Raptor system integration products. Since 1984, our wired and wireless monitoring systems have provided peace of mind for facility stakeholders and over 17 million feet of our patented leak detection cable is installed in facilities worldwide.

Additional information can be found at https://www.rletech.com

###

RLE Technologies Launches Wi-Fi Temperature and Humidity Sensor

Fort Collins, CO – August 13, 2019 — RLE Technologies, a leading provider of web-based monitoring solutions and leak detection systems for mission-critical facilities, is excited to introduce the WIFI-TH - a wireless temperature and humidity sensor that leverages an existing Wi-Fi network to communicate with a building management system.

“As Wi-Fi technology evolves to become cheaper, more reliable, and more secure, we’ve noticed that many of our customers are using Wi-Fi to power their networks,” says Ryan Clemens, a Senior Firmware Engineer at RLE. “We wanted to provide a sensor with RLE’s quality and reliability that could quickly and easily integrate into these environments.”

Jeremy Swanner, RLE’s President, agrees, “Over the past two years, RLE’s wireless sensors have set the benchmark for affordability, battery life, transmission range, and integration. Going into this project we knew the WIFI-TH would have to meet the same criteria, and it absolutely does.”

The WIFI-TH is wireless and battery powered. Since wires are not required for power or transmission, an electrician isn’t required for installation. Plus, RLE’s Wi-Fi sensors are compact, unobtrusive, and provide an industry leading battery life – up to seven years at a five minute transmission interval.

The WIFI-TH’s temperature and humidity data can be sent via a UDP packet to a BMS system or pulled into RLE’s WiNG-MGR. And while IT departments may be hesitant to add wireless devices, it will ease their mind to know that these sensors were designed with security in mind. The WIFI-TH:

- Only allows one-way communications, so there is no risk they could be hacked remotely.

- Fully supports industry standard WPA/WPA2‑PSK encryption.

- Features encrypted data storage for network and configuration information.

Facilities worldwide are using RLE’s WIFI-TH to monitor for changes in temperature and humidity, meet efficiency goals, maintain optimal equipment performance parameters, anticipate equipment failures, and prevent downtime. The WIFI-TH is in stock and ready to ship!

About RLE Technologies

RLE Technologies is the global provider of Triad raised floor and airflow products, SeaHawk leak detection, Falcon facility monitoring solutions, and Raptor system integration products. Since 1984, our wired and wireless monitoring systems have provided peace of mind for facility stakeholders and over 16 million feet of our patented leak detection cable is installed in facilities worldwide.

Additional information can be found at https://www.rletech.com

###

RLE Technologies Introduces Facility Monitoring with

Seamless BMS Integration

WiNG, Leak Detection, and 1-Wire Modules Now Available

Fort Collins, CO – February 12, 2019 — RLE Technologies, a leading provider of web-based monitoring solutions and leak detection systems for mission-critical facilities, has added a new line of panel-mount monitoring devices designed specifically for system integration. These new Building Management System (BMS) modules use protocols to communicate directly with any Modbus RTU or BACnet MS/TP system.

“When we developed the BMS products, our main goal was to make them as simple and straightforward as possible,” says RLE’s Senior Firmware Engineer Ryan Clemens. “For customers who would like to monitor legacy equipment or other equipment not designed with BMS systems in mind, we’ve designed a new line of products that easily integrate into an RS-485 based BACnet or Modbus trunk.”

With no user interface or separate software required, these modules make RLE’s sensor technology readily accessible and seamlessly integrateable for an entirely new segment of customers.

“We understand how valuable that BMS ‘single pane of glass’ view is to our customers,” says Jeremy Swanner, President, RLE Technologies. “These new products work behind the scenes to expand the capabilities of that BMS framework they’re already comfortable with.”

All three new products are in stock and ready to ship.

- BMS-WiNG– Integrate up to 50 WiNG sensors monitoring a variety of conditions including temperature, humidity, differential pressure, and airflow. Available in 900MHz and 868MHz configurations for domestic and international installations.

- BMS-LD3Z– Protect a facility from costly water damage with 3 zones of RLE’s patented leak detection. The BMS-LD3Z continuously monitors sensing cable for leaks, breaks, and disconnects and sends an alarm when one is detected.

- BMS-1WIRE– Quickly add up to 8 plug-and-play wired temperature or temperature/humidity sensors. RLE’s 1-wire sensors are a cost-effective way to monitor for overheating or excessive humidity conditions in equipment that you otherwise would not be able to monitor with a BMS.

About RLE Technologies

RLE Technologies is the global provider of Triad raised floor and airflow products, SeaHawk leak detection, Falcon and WiNG facility monitoring, and Raptor system integration products. For more than 35 years, our wired and wireless monitoring systems have provided peace of mind for facility stakeholders, and over 16 million feet of our patented leak detection cable is installed in facilities worldwide.

Additional information can be found at https://www.rletech.com

###

RLE Technologies Brings Wireless Monitoring to Global Market

Popular WiNG Products Now Available Worldwide

Fort Collins, CO – September 25, 2018 — On the heels of an overwhelmingly successful US domestic product adoption, RLE Technologies, a leading provider of web-based monitoring solutions and leak detection systems for mission-critical facilities, announces the full release of the WiNG wireless monitoring platform in both 868MHz and 900MHz frequencies. The complete suite of WiNG wireless monitoring products is now available for installation in data centers and critical facilities worldwide.

“The market acceptance of our 900MHz WiNG products has exceeded every one of our projections,” says Jeremy Swanner, President, RLE Technologies. “WiNG meets our customers’ needs and expectations, which is reflected in its rapid adoption as the new standard in wireless monitoring. We are excited to launch WiNG onto the global stage.”

WiNG offers a complete suite of wireless sensors, network managers, and range extenders. Customers are impressed with WiNG’s unparalleled suite of features, available on both the 868MHz and 900MHz frequency versions of the monitoring platform:

- Battery Life: WiNG sensors provide an industry leading battery life – sensor batteries last up to 12 years at room temperatures. WiNG sensors maintain this extended battery life while communicating readings to the WiNG-MGR every 10-20 seconds.

- Transmission Range: The WiNG system has an unprecedented transmission range: up to 600 feet indoor, direct line of sight. While this range is more than ample for most situations, sometimes applications require signals to be pushed through more complex physical or noisy RF environments. The WiNG-RXT range extender can be implemented in these situations to add up to 1,000 feet direct line of sight transmission distance to the application.

- Transmission Accuracy: WiNG demonstrates an accuracy of data packet transmission above 98%. This means the data you see is accurate and timely.

- Open Protocol Communication: The WiNG-MGR includes SNMP, Modbus, and BACnet protocols for integration into a larger BMS.

- No Recurring Costs: The WiNG-MGR hosts its own web pages and you own all of your data – with absolutely no subscriptions or additional fees.

Swanner is enthusiastic about this product rollout, “Our SeaHawk orange leak detection cable and Falcon FMS monitoring products are already well known in International markets. We’ve built the same reliability and quality into our WiNG products, and we’re excited to show our customers how WiNG can be used to wirelessly monitor their unique facility needs.”

WiNG managers, sensors, and range extenders are in stock and available now for immediate shipment.

About RLE Technologies

Deployed in data centers and critical facilities worldwide, RLE’s portfolio of products includes: Triad raised floor and airflow products, SeaHawk leak detection, Falcon and WiNG facility monitoring equipment, and Raptor system integration solutions. With over 16 million feet of patented leak detection cable in service worldwide, RLE is a proven industry leader in the leak detection and monitoring arena.

Additional information can be found at https://www.rletech.com

###

RLE Technologies Names Tim Hirschenhofer Senior Vice President of Operations

Move Aligns Organization Effectively For Projected Growth

Fort Collins, CO – July 17, 2018 — RLE Technologies, a leading provider of raised floor and airflow products, web-based monitoring solutions, and leak detection systems for mission-critical facilities, announced today that it has promoted Tim Hirschenhofer to Senior Vice President of Operations.

Fort Collins, CO – July 17, 2018 — RLE Technologies, a leading provider of raised floor and airflow products, web-based monitoring solutions, and leak detection systems for mission-critical facilities, announced today that it has promoted Tim Hirschenhofer to Senior Vice President of Operations.

“We’ve seen two years of solid, robust growth,” says Jeremy Swanner, President, RLE Technologies. “We have every indication and expectation that this growth will continue. Now is the time to ensure the right people are in the right roles at RLE. Tim’s been a big part of this growth through the four years he’s been with RLE and his background and experience make him ideally suited for this position.”

Tim’s background includes supporting organizations in a technical manner, with a focus on manufacturing processes and end user technical assistance. His previous experience includes production process engineering for the high tech computer industry, developing and improving products supporting the manufacturing and inspection of semiconductors, and implementing ISO manufacturing standards. Tim has spent the last 12 years of his career supporting product development and engineering projects related to efficiency improvements in data centers. He brings a wealth of knowledge related to the data center industry and the critical aspect of product performance in this environment.

“RLE is known for its excellent customer service and we’re very proud of that,” notes Hirschenhofer. “As we grow, we need to ensure partners and customers continue to receive the best possible customer service experience and the shortest possible lead times for products and services. We have a top-notch manufacturing and technical support team in place, and it’s my goal to make sure they have all the resources and processes in place to operate productively and efficiently.”

Tim will take a very active role in capacity planning, vendor relationships, cost containment, and efficiency gains, as well as strategic growth for the future. A testament to his foresight, Tim’s leadership has already guided RLE through a $500,000 investment in automation equipment which increases production capacity by 300% - containing labor costs while increasing production capabilities.

About RLE Technologies

For more than 30 years, RLE Technologies has designed, engineered, and manufactured innovative technologies that support our overarching company mission: to prevent disasters, preserve our customers’ reputations, and provide customers with valuable peace of mind. Deployed in data centers and critical facilities worldwide, our portfolio includes: Triad raised floor and airflow products, SeaHawk leak detection, Falcon monitoring equipment, Raptor integration solutions, and RLE Services which offers system startup, commissioning, and product training services. Clients worldwide rely on RLE’s patented products to detect threats, notify stakeholders, and mitigate risks to critical sensitive environments, and with over 16,000,000 feet of patented leak detection cable in service worldwide, RLE is a proven industry leader in the facility monitoring arena.

Find additional information at https://www.rletech.com

###

RLE Technologies Introduces Low Smoke Zero Halogen Leak Detection Sensing Cable

Patented, Reliable Leak Detection Cable Now Available In Low Smoke Zero Halogen Composition

Fort Collins, CO – April 18, 2018 — RLE Technologies, a leading provider of web-based monitoring solutions and leak detection systems for mission-critical facilities, announced today that it has added a new product to their leak detection portfolio of products: low smoke zero halogen leak detection sensing cable.

RLE’s low smoke zero halogen (LSZH) cable responds to leaks in just the same way and just as quickly as the company’s orange leak detection sensing cables – water is detected and a signal is sent back to the leak detection controller, identifying the leak and sending notification to responsible parties immediately. In addition, LSZH cable is specifically formulated to release significantly less smoke and zero halogen upon combustion. In the event of a fire the smoke released by the LSZH cable is lower in quantity, less optically dense (easier to see through), and releases fewer toxic and corrosive gases than other leak detection cables. This makes exiting a space safer for employees and accessing the source of a fire easier for emergency personnel. These intrinsic characteristics make RLE’s LSZH cable an excellent fit for specialty installs and applications with limited ventilation including subway tunnels, nuclear power plants, aircraft, tanks, ships and submarines, and subsea or offshore installations.

“We’ve been in the leak detection marketspace for more than 30 years,” says Don Raymond, RLE’s CTO and Founder. “We’ve learned to listen to the ever-changing needs of our customers, and have seen our products deployed in areas with specific sets of requirements. The addition of this low smoke zero halogen cable lets us meet the needs of these facilities’ specialized requirements while providing the standard of leak detection that RLE is known for.”

RLE’s LSZH cable can be used inline with their patented orange leak detection sensing cable and can be used in new applications and integrated seamlessly into any existing RLE leak detection monitoring systems. LSZH cable is in stock now and available for immediate shipment.

About RLE Technologies

For more than 30 years, RLE Technologies has designed, engineered, and manufactured innovative technologies that support our overarching company mission: to prevent disasters, preserve our customer’s reputations, and provide every customer with valuable peace of mind. Deployed in data centers and critical facilities worldwide, our portfolio includes: Triad raised floor and airflow products, SeaHawk leak detection products, Falcon facility monitoring equipment, Raptor system integration solutions, and our RLE Services which offers complete system startup, commissioning, and product training services. Thousands of customers worldwide rely on RLE’s patented products to detect threats, notify stakeholders, and mitigate risks to their critical sensitive environments, and with over 16 million feet of our patented leak detection cable in service worldwide, RLE is a proven industry leader in the leak detection and monitoring arena.

Additional information can be found at https://www.rletech.com

###

RLE Technologies Launches buy.rletech.com

Ecommerce site allows customers to shop for and purchase industry-leading leak detection, airflow, and environmental monitoring products 24x7

Fort Collins, CO – November 14, 2017 — RLE Technologies, a leading provider of web-based monitoring solutions and leak detection systems for mission-critical facilities, announced today that it has launched an ecommerce website: buy.rletech.com.

Fort Collins, CO – November 14, 2017 — RLE Technologies, a leading provider of web-based monitoring solutions and leak detection systems for mission-critical facilities, announced today that it has launched an ecommerce website: buy.rletech.com.

Buy.rletech.com offers a selection of RLE’s and Triad’s most frequently purchased products and provides customers with a highly visual and direct way to purchase either full monitoring and flooring systems or components to add to their existing product installs.

“We are so excited to launch our ecommerce site,” says Jenny Peterson, RLE’s Manager of Marketing and Communications. “People’s expectations of an online purchase experience have definitely evolved, and it’s our job to evolve with them. The new site really follows the familiar flow of our main website and makes it very easy for customers to pick, purchase, and ship our products straight to their doorstep, any time, day or night.”

“We’ve been planning an ecommerce site for quite a while and it’s really rewarding to see it come to fruition,” says Jeremy Swanner, President of RLE Technologies. “Providing a path for customers to order and receive our products quickly and efficiently is a win for our customer base and a win for RLE as well.”

About RLE Technologies

RLE Technologies is a leading global provider of critical facility oversight and notification. For more than 30 years, RLE has delivered facility monitoring and leak detection technologies that prevent disasters, preserve our customers’ reputations, and provide peace of mind. Our portfolio includes a variety of solutions to accomplish these important goals: SeaHawk for Leak Detection, Falcon for Facility Monitoring, Raptor for System Integration, Triad for Raised Floors, and our RLE Services. Thousands of customers world-wide rely on RLE products to detect threats, notify stakeholders, and mitigate risks to their critical sensitive environments.

Additional information can be found at http://www.rletech.com

###

Triad Floors Announces New Addition to Product Line with Competitively Priced High Flow Aluminum Grate

New raised floor tile introduced as a response to customer feedback; provides opportunity for airflow efficiency at a lower price point.

Fort Collins, CO – August 23, 2017 – Triad Floors, a division of RLE Technologies and a leader in high-performance airflow panels for raised floor data centers, announced today that it has added a new airflow panel to its data center raised floor line of products. Triad’s new Aluminum Grate panel will be in stock and ready to ship on September 1st, 2017.

Designed to fit most existing imperial (24” x 24”) dimensioned raised floors, the new high performance cast aluminum panel has a 1,250 pound load rating and is offered in Triad’s Crystal White and Grey Flek powder coat colors. Users appreciate the tile’s 55% effective open area which helps facilities meet high-flow cooling requirements. An extremely competitive price point means the new Aluminum Grate provides Triad customers with a quality, proven data center cooling and airflow solution at a price previously unavailable in Triad’s portfolio.

“We are always listening to feedback from our customers,” said Tim Hirschenhofer, Triad Senior Vice President. “When we learned of the need for an aluminum tile, and how the addition of this product would benefit our customer base, the decision was easy.”

“We are excited to add this new product to Triad Floors’ line of raised floor cooling solutions”, said RLE President, Jeremy Swanner. “We’re fortunate to be in a position where we can respond quickly to the needs of our marketspace. Getting this product to market so fast was truly a team effort that required coordination among all levels of our business. We’ll continue to evaluate industry needs and respond to evolving customer requirements, so we can maintain the company/customer relationship that our base appreciates.”

About RLE Technologies

RLE Technologies is a leading global provider of critical facility oversight and notification. For more than 30 years, RLE has delivered facility monitoring and leak detection technologies that prevent disasters, preserve our customer’s reputations, and provide peace of mind. Our portfolio includes a variety of solutions to accomplish these important goals: SeaHawk for Leak Detection, Falcon for Facility Monitoring, Raptor for System Integration, Triad for Raised Floors, and our RLE Services. Thousands of customers world-wide rely on RLE products to detect threats, notify stakeholders, and mitigate risks to their critical sensitive environments.

Additional information can be found at https://www.rletech.com.

About Triad Floors Inc.

Triad Floors, a division of RLE Technologies, is a leader in manufacturing high-performance airflow panels for raised floor data center environments. In response to the need for an efficient cooling panel that would fit into any new or existing raised access floor systems, Triad designed and patented cooling airflow panels that allow for an increase in rack density while remedying data center and server farm hotspot challenges.

Additional information can be found at https://www.triadfloors.com

###

RLE Technologies Acquires Triad Floors from NxGen

Strategic acquisition will enable critical facility monitoring and leak detection leader to diversify offerings with addition of data center airflow optimization and underfloor cooling solutions

![]() Denver & Fort Collins, CO – April 25, 2017 – RLE Technologies, a leading provider of web-based monitoring solutions and leak detection systems for mission-critical facilities, formally announced today the acquisition from NxGen of Triad Floors, a prominent manufacturer of data center floor tiles and effective airflow solutions. The transaction was approved by the Boards of Directors of both companies on April 10, 2017.

Denver & Fort Collins, CO – April 25, 2017 – RLE Technologies, a leading provider of web-based monitoring solutions and leak detection systems for mission-critical facilities, formally announced today the acquisition from NxGen of Triad Floors, a prominent manufacturer of data center floor tiles and effective airflow solutions. The transaction was approved by the Boards of Directors of both companies on April 10, 2017.

The acquisition adds a new level of diversity to RLE Technologies’ product portfolio, which has become an industry leader in the protection of data centers and other mission critical facilities through environmental threat detection and web-based monitoring solutions. The firm will now provide a wide variety of raised floor data center solutions, including Triad’s patented high-flow panels, as well as a number of additional airflow and cooling improvement options which help customers achieve industry-leading data center Air Utilization Efficiency (AUE) scores. Triad Floors is also the creator of the River Cooling System, which provides reductions of up to 40% in data center cooling energy costs by replacing ineffective airflow systems with improved Fluid Dynamics Management.

The genesis of the acquisition comes from a strategic planning process RLE Technologies underwent in 2016, which resulted in a restructuring of the firm’s management team. It also identified revenue diversification as a new primary goal for the company, and the purchase of Triad Floors will go far to add an array of complimentary offerings for the data center and mission critical space. Both firms are based in Colorado and manufacture their products in the state.

“The combination of RLE Technologies and Triad Floors presents a significant opportunity to better protect data centers worldwide,” said Jeremy Swanner, President of RLE Technologies. “Triad Floors has built its reputation as data center cooling and airflow systems experts for more than 10 years. With this announcement, RLE Technologies is able to provide data center owners and operators with a more diverse set of solutions to help them maintain uptime in the future.”

As part of the agreement, all current Triad Floors employees will be retained in their present roles. Gary Meyer, the founder and owner of both NxGen and Triad Floors, will be intimately involved in the transition, future company growth and new product development. Tim Hirschenhofer, the new Senior Vice President of Triad Floors, will be responsible for business development and operations. An industry veteran, Hirschenhofer brings more than 15 years of experience in data center airflow and energy optimization to his new position.

“As technology continues to integrate into our professional and personal lives, the ability to protect the infrastructure that keeps it running becomes even more paramount,” said Gary Meyer, founder and owner of NxGen/Triad Floors. “By leveraging the combined solutions and capacity of RLE Technologies and Triad Floors, the data center industry is in a much better position to accomplish this important goal. I look forward to seeing the tremendous growth opportunities that this combination will provide both domestically and abroad as well as the new technologies that will emerge from this partnership.”

About RLE Technologies

RLE Technologies is a leading global provider of critical facility oversight and notification. For more than 30 years, RLE has delivered facility monitoring and leak detection technologies that prevent disasters, preserve our customer’s reputations, and provide peace of mind. Our portfolio includes a variety of solutions to accomplish these important goals: SeaHawk for Leak Detection, Falcon for Facility Monitoring, Raptor for System Integration, and our RLE Services. Thousands of customers world-wide rely on RLE products to detect threats, notify stakeholders, and mitigate risks to their critical sensitive environments.

Additional information can be found at http://www.rletech.com.

About Triad Floors Inc.

Founded in 2003, Triad Raised Floor Company provides a full suite of airflow and raised floor panels, hot/cold aisle containment solutions, and blanking panels that are designed to increase cooling, lower costs, and maintain uptime for the data center industry.

In response to the need for an efficient cooling panel that would fit into new or existing raised access floor systems, Triad Floors created the passive "River Cooling System©.” This innovative design increases server airflow density while remedying data center and server farm hotspot challenges.

Triad Floors guarantees that they can fit any raised floor design without modification to the existing raised floor system and all of the company’s distribution is proudly done in Colorado. Triad Floors also administers a global distribution network to provide rapid response and support anywhere in the world.

###

Instor and Digital Realty to Host Complimentary Data Center End-User Event in Santa Clara

Held at Digital Realty’s campus, program will illustrate how to transform white space into a high-performance, energy efficient data center

Santa Clara, CA – April 14, 2017 – Instor Solutions, Inc, RLE Technologies, and Upsite Technologies, today announced a complimentary event for data center operators at Digital Realty’s Santa Clara, Calif. facility. Titled Beyond Whitespace, the seminar will be held on April 27, 2017 from 8:00 a.m. – 12:00 p.m. Attendees are invited to tour the data center at the conclusion of the event.

Effectively expanding or building out whitespace into an efficiently running data center requires the ability to be prepared for unexpected circumstances. After working in hundreds of data centers around the globe, Instor, RLE, and Upsite each bring a unique perspective and lessons learned from a multitude of examples and challenging scenarios.

Leading the discussion, Instor, an expert in building out data center whitespace, will outline the composition of full-suite environments, relationship between IT systems and physical assets, and how to understand expansions with attention to both current goals and future needs. RLE Technologies, a leader in mission critical leak detection and environmental monitoring solutions, will explore why current operations look to DCIM solutions, how monitoring whitespace makes a difference, and what the implementation of these solutions entails. To conclude, Upsite Technologies, an industry authority on data center airflow management, will examine the science of airflow and available best practices for immediately improving operational efficiency.

Mark Bramfitt, former designer and director of PG&E’s data center and IT program, will moderate Beyond Whitespace and present on energy trends and their impact on data center operations, how the industry has evolved over the last decade, and the role of Cloud adoption in data centers.

“The changing capacity required of a data center environment as well as a data center’s energy use together create one of the most difficult and complex operational landscapes to manage both efficiently and effectively,” said Mark Bramfitt, Utility and Information Technology Industry Strategic Engagement Consultant. “The three presentations at Beyond Whitespace will explore best practices pulled from hundreds of case studies from data centers across the country as well as offer attendees actionable advice for whitespace expansion, environmental monitoring, and airflow management. Instor, RLE, and Upsite present a holistic understanding of whitespace and the immediate improvements available to data center operators facing a wide variety of challenges.”

Digital Realty’s data centers in Santa Clara, Calif. offer premium interconnection and colocation services. An executive from Digital Realty will spend time at this event speaking about how the world-famous center of innovation and technology, Santa Clara, also offers demonstrable advantages in location, infrastructure, low operating costs, low-cost energy—including the Bay area’s lowest utility rates—and a business-first attitude.

Additional details and registration for Beyond Whitespace can be found here.

About Digital Realty

Digital Realty supports the data center and colocation strategies of more than 2,200 firms across its secure, network-rich portfolio of data centers located throughout North America, Europe, Asia and Australia. Digital Realty’s clients include domestic and international companies of all sizes, ranging from financial services, cloud and information technology services, to manufacturing, energy, gaming, life sciences and consumer products.

Additional information can be found at www.digitalrealty.com

About Instor Solutions, Inc

Instor Solutions, Inc collaborates with high-growth startups to Fortune 1000 companies providing customized data center infrastructure solutions facilitating individual data center needs. Instor builds out wholesale colocation, lab, and data center spaces from whitespace to operation ready. Instor’s specialized data center fit up service reduces overall build time and project costs. Instor is an industry leader in data center design, structured cabling, power infrastructure, and specialized containment and cooling solutions. With over 25 years of experience, Instor is headquartered in the San Francisco Bay Area. Instor has complete North American coverage with regional hubs in the Ashburn Area and the Dallas-Fort Worth Area. Instor has capabilities extending to Europe with a European headquarters based in Dublin, Ireland.

Additional information can be found at www.instor.com

About RLE Technologies

RLE Technologies is a leading global provider of leak detection and monitoring solutions for critical facilities; more than 14 million feet of our leak detection cable is currently in service, preventing fluid damage in facilities worldwide. Heralded for our protocol integration capabilities and tip-tier reliability, our portfolio includes our patented SeaHawk leak detection cable and controllers, Falcon monitoring products, and Raptor integration solutions. With more than 30 years of experience in our industry, we hold nine patents for our innovative products and the technology that powers our leak detection and facility monitoring controllers. We are committed to preventing disasters, preserving our customers’ reputations, and providing stakeholders with peace of mind.

Additional information can be found at www.rletech.com

About Upsite Technologies

Upsite Technologies®, Inc. is an industry leader in data center airflow management and cooling. Upsite provides a full suite of products and services designed to optimize data center cooling systems, allowing managers to maximize cooling capacity while reducing energy costs. Upsite distributes its award-winning line of services and products, including KoldLok®, HotLok®, AisleLok®, and EnergyLok® through leading channel partners in the data center industry throughout the United States, EMEA and the Asia Pacific regions. Upsite Technologies, Inc. was founded in 2001 by Ken Brill, creator of the Uptime Institute, a think tank dedicated to understanding, improving, educating and expanding awareness of uptime and inefficiencies in data centers.

Additional information can be found at www.upsite.com

###

RLE Technologies Named to CRN’s Data Center 100 List for 2017

Awarded as one of the top 20 data center management providers, firm selected due to its expertise in detecting data center environmental hazards and protecting sensitive facilities from threats

Fort Collins, CO – April 3, 2017 – RLE Technologies, a leading provider of web-based monitoring solutions and leak detection systems for mission-critical facilities, announced today that CRN®, a brand of The Channel Company, has named the firm to its 2017 Data Center 100 list. Recognizing the technology suppliers that excel at powering, supporting and protecting the complex and demanding data centers on which today’s businesses rely, the annual list highlights the providers that represent their respective fields with a combination of innovation, market share, and technology and channel capabilities.

Fort Collins, CO – April 3, 2017 – RLE Technologies, a leading provider of web-based monitoring solutions and leak detection systems for mission-critical facilities, announced today that CRN®, a brand of The Channel Company, has named the firm to its 2017 Data Center 100 list. Recognizing the technology suppliers that excel at powering, supporting and protecting the complex and demanding data centers on which today’s businesses rely, the annual list highlights the providers that represent their respective fields with a combination of innovation, market share, and technology and channel capabilities.

Named among only 20 other companies, RLE Technologies is recognized in CRN’s “Data Center Management Provider” category. The listing highlights RLE Technologies’ many tools that detect environmental hazards. Within its portfolio of leak detection and facility monitoring equipment, the company offers a variety of solutions, including: fluid detection cabling, spot detectors, facility monitoring systems, and an assortment of both wired and wireless sensors that monitor environmental conditions (temperature, humidity, smoke and others). Additionally, RLE Technologies directs a robust channel program that includes more than 80 partners.

“We are delighted to be recognized as one of CRN’s top 20 Data Center Management Providers,” said Jeremy Swanner, President of RLE Technologies. “For more than 30 years, RLE has worked to protect data centers and other critical facilities from environmental hazards. Despite the continuous advancement of data center solutions, the need to stay ahead of the many threats that data centers face remains a constant. In an industry where seconds of downtime can have far-reaching impacts, it is rewarding to see RLE Technologies recognized by such a reputable organization in the data center space.”

CRN editors select companies for the Data Center 100 list on the basis of multiple criteria, including each company's overall impact on the market, its influence on the channel as a whole, and the types of technology and services it makes available to its partners.

“The construction and operation of a reliable data center requires wide-ranging expertise and resources across a number of key technologies,” said Robert Faletra, CEO of The Channel Company. “Our annual Data Center 100 list identifies the top vendors in these areas, helping solution providers find proven data center experts such as RLE Technologies, who can deliver the necessary depth and breadth of materials, services and expert guidance.”

In addition to recognizing technology suppliers for outstanding products and services, the Data Center 100 serves as a valuable guide for solution providers looking for best-in-class vendors providing data center infrastructure, data center management tools, software-defined data center technology and data center services. The Data Center 100 list can be found at: www.crn.com/datacenter100.

About RLE Technologies

RLE Technologies is a leading global provider of critical facility oversight and notification. For more than 30 years, RLE has delivered facility monitoring and leak detection technologies that prevent disasters, preserve our customer’s reputations, and provide peace of mind. Our portfolio includes a variety of solutions to accomplish these important goals: SeaHawk for Leak Detection, Falcon for Facility Monitoring, Raptor for System Integration, and our RLE Services. Thousands of customers world-wide rely on RLE products to detect threats, notify stakeholders, and mitigate risks to their critical sensitive environments.

Additional information can be found at http://www.rletech.com

Copyright ©2017. The Channel Company, LLC. CRN is a registered trademark of The Channel Company, LLC. All rights reserved.

###

RLE Technologies Receives Patent for Embedded Mapping in Nested Facility Management Devices

Latest patent awarded for innovative mapping and nesting features that employ a distributed monitoring model in facility management systems

Fort Collins, CO – January 25, 2017 – RLE Technologies, a leading provider of web-based monitoring solutions and leak detection systems for mission-critical facilities, announced today that it has been awarded a patent by the United States Patent and Trademark Office for its Facilities Management System. This newly patented technology provides a highly interactive, visual representation of the facilities, sites, and equipment monitored by RLE environmental monitoring devices.

U.S. Patent No. 9,420,042, entitled “Facilities Management System” and marketed by RLE Technologies as Delta View, encompasses both the unique nesting feature currently used in RLE Technologies’ Falcon product line as well as the interactive mapping feature used in both the Falcon and SeaHawk product lines. Nesting allows a system of facilities management devices and sensors to be networked through linked map images. The visual links change state to report the existence of alarm conditions. This allows users to quickly analyze data from their connected equipment and immediately locate the sensor or networked hardware that has activated the alarm. The innovative technology integrates various management systems and communications protocols and provides a wide range of options for facility managers as their monitoring needs expand.

The new patent also covers the mapping technology found in both the Falcon monitoring system and a variety of RLE Technologies’ leak detection solutions. Interactive mapping allows users to upload a graphic (such as a facility map) to the facility management system and pinpoint the location of their monitoring tools which can include sensors, leak detection cable points, and other hardware devices. When alerts from these devices and points are activated, facility managers have a clear idea where the alarm is located and can rapidly respond to and address the problem.

“As critical facilities continue to grow in size and complexity, difficulties in their accurate and timely monitoring have been compounded,” said Don Raymond, Chief Technology Officer of RLE Technologies and co-inventor of the new system. “The distributed monitoring model within the Delta View nesting technology allows one facility monitoring system to be the single pane of glass for thousands of other linked monitoring systems, all of which have mapping capabilities. This allows facility managers to quickly identify which device is the source when an alarm occurs and gives them the opportunity to solve a problem before it can cause downtime.”

Don Raymond is one of the founding partners of RLE Technologies and has been developing new techniques and products to protect mission critical facilities for more than 30 years. In pursuit of this goal, he has been awarded nine patents.

About RLE Technologies

RLE Technologies is a leading global provider of critical facility oversight and notification. For decades, RLE has delivered facility monitoring and leak detection technologies that prevent disasters, preserve our customer’s reputation, and provide peace of mind. Thousands of customers world-wide rely on RLE products to detect threats, notify stakeholders, and mitigate risks to their critical sensitive environments.

Additional information can be found at http://www.rletech.com.

###

RLE Technologies Appoints Jeremy Swanner President

Critical facilities monitoring and leak detection leader to continue positive growth under industry veteran

Fort Collins, CO – November 15, 2016 – RLE Technologies, a leading provider of web-based monitoring solutions and leak detection systems for mission-critical facilities, announced today the appointment of Jeremy Swanner as the company’s President. Mr. Swanner assumes the new leadership position from his previous role of Executive Vice President at RLE Technologies. In this new capacity, Mr. Swanner will be responsible for continuing the company’s steady growth in the data center and facilities markets, expanding its robust channel program, and overseeing its general operations, including: product innovation and development, customer support, and business development.

Fort Collins, CO – November 15, 2016 – RLE Technologies, a leading provider of web-based monitoring solutions and leak detection systems for mission-critical facilities, announced today the appointment of Jeremy Swanner as the company’s President. Mr. Swanner assumes the new leadership position from his previous role of Executive Vice President at RLE Technologies. In this new capacity, Mr. Swanner will be responsible for continuing the company’s steady growth in the data center and facilities markets, expanding its robust channel program, and overseeing its general operations, including: product innovation and development, customer support, and business development.

“Data centers and critical facilities provide the crucial backbone for a variety of industries that affect our daily lives,” said Don Raymond, Founder and Chief Technology Officer of RLE Technologies. “Throughout his career, Jeremy’s results-oriented approach and unique business acumen have played a vital role in increasing strategic partnerships and driving sales at a number of companies. He has an impressive record of success in this marketplace and I am delighted that he has agreed to be the next President of RLE Technologies.”

Prior to joining RLE Technologies in 2012, Mr. Swanner worked in a leadership capacity for a variety of companies, including: National Sales Director for Staples’ Corporate Express Imaging and Computer Graphic Supplies as well as Director of Channel Sales for Server Technology. Mr. Swanner’s new appointment comes at a significant time for RLE Technologies, as several high profile outages in mission critical industries have occurred over the last several months, underscoring the important role that monitoring solutions play in avoiding downtime.

“For more than 30 years, RLE Technologies has been both a market leader and innovator in how monitoring technology can be utilized to benefit critical facilities,” said Jeremy Swanner, President of RLE Technologies. “I am privileged to lead an experienced team as we work to help companies stay ahead of potential threats, maintain uptime, and increase their operational performance through the use of the most advanced tools and technology available. I look forward to building on the success that RLE Technologies has earned while expanding its reach into new industries.”

About RLE Technologies

RLE Technologies is a leading global provider of critical facility oversight and notification. For decades, RLE has delivered facility monitoring and leak detection technologies that prevent disasters, preserve our customer’s reputation, and provide peace of mind. Thousands of customers world-wide rely on RLE products to detect threats, notify stakeholders, and mitigate risks to their critical sensitive environments.

Additional information can be found at http://www.rletech.com

###

RLE Technologies Releases Top Five Points of Protection for a Leak-Free 2015

An expert in leak detection, RLE Technologies explains what to consider to ensure a leak-free mission critical facility in the New Year

Fort Collins, CO – December 10, 2014 – RLE Technologies, a leading provider of water leak detection systems and web-based monitoring solutions for mission-critical facilities, today released its list of the top five threats for leaks in a mission critical facility and how to solve these issues, determined by its experts in leak detection and experience in data centers across the nation.

In an industry where just seconds of downtime represent enormous bottom line implications, leak detection and monitoring are crucial elements to consider in a highly sensitive facility. These five areas of focus are the most frequent points of failure from a fluid intrusion perspective:

- Faulty Mechanical Equipment: Uncapped sprinkler lines, leaky storage tanks, improperly monitored A/C units, leaking water filter units.

- Structural Failures: Leaky roofs, improperly installed windows, clogged drains, overall general faulty construction.

- Piping issues: Failing pipes/fittings/valves, freezing pipes, fluid hammer effect (a pressure build-up when fluids stop or change directions suddenly), faulty pipes in primary plumbing walls.