Rodent Resistant Leak Detection

RLE’s rodent resistant sensing cable reliably detects the presence of water leaks and other conductive fluids while discouraging rodents from chewing on and subsequently damaging the cable. The sensing cable features chemical additives and a cable color that are unpleasant in odor and taste to rodents, which discourages gnawing, chewing, and other rodent contact.

RLE’s conductive fluid sensing cable is:

-

- Durable – manufactured with an abrasion-resistant polymer core, which increases strength and durability. Definitely stands up to foot traffic!

-

- Flexible – easily bends around corners and wraps around pipes, while resisting bends and kinks.

-

- Resists False Alarms – engineered specifically to resist contamination and constructed from non-conductive polymers to help eliminate false alarms!

-

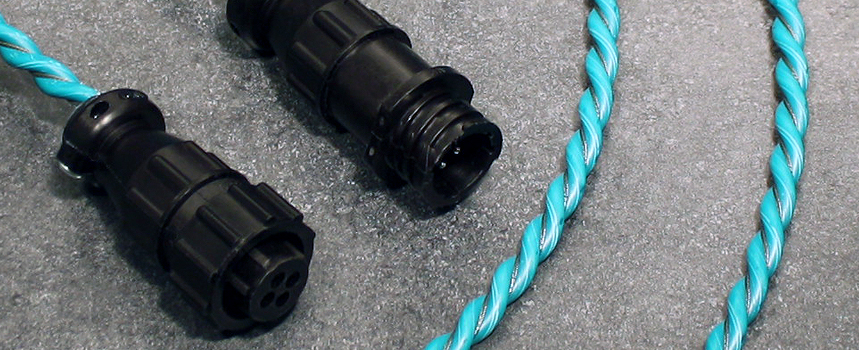

- Quick to Install – each end of the cable contains mating connectors – this makes it easy to install new systems and to add lengths of cable to existing systems.

-

- Easy to Clean – when it’s visibly dirty, clean it quickly with Dawn dish soap or rubbing alcohol. No special cleaners or cleaning systems required.

-

- Fast Drying – gently wipe the cable dry, and it’s ready to detect the next leak.

Liquid Cooling Protection

Confidently protect your liquid cooled or air cooled data centers with RLE’s leak detection solutions. All SeaHawk leak detection cables support detection of leaks of Propylene Glycol/water mixtures. We support detection blends with up to 35% Propylene Glycol (by weight) including PG15, PG25 and PG35.

Sensing cables are available in a variety of standard and custom lengths:

- 3ft (0.91m) – SC-R-3

- 10ft (3.05m) – SC-R-10

- 17ft (5.18m) – SC-R-17

- 25ft (7.62m) – SC-R-25

- 50ft (15.24m) – SC-R-50

- 100ft (30.48m) – SC-R-100

- Custom Lengths (available upon request) – SC-R-CL

With over 20 million feet of leak detection sensing cable installed in systems around the globe, you can’t beat the durability or reliability of our leak detection sensing cables.

How Much Cable Do I Need?

Ready to purchase a SeaHawk system? Download and use our SeaHawk Sensing Cable Length Calculator to make sure you order the right amount of cable.