Patented Leak Detection, Resists Chemical Corrosion

RLE’s green chemical sensing cable is used to reliably detect leaks via the presence of acids, bases, and other conductive liquids. RLE has held a patent on this particular cable since 2012. It affords users with all the same benefits as our orange conductive fluid sensing cable, plus:

-

- It’s Resistant to Chemical Corrosion – This is why we developed chemical sensing cable. Our customers wanted to detect leaks in more challenging environments, and they clamored for a cable-based solution. Our chemical sensing cable is constructed of components that are inert to most chemicals. That’s right – expose it to corrosive chemicals and it won’t break down. That means you can detect leaks of corrosive aqueous chemicals, and detect leaks in environments where other cables will decompose.

-

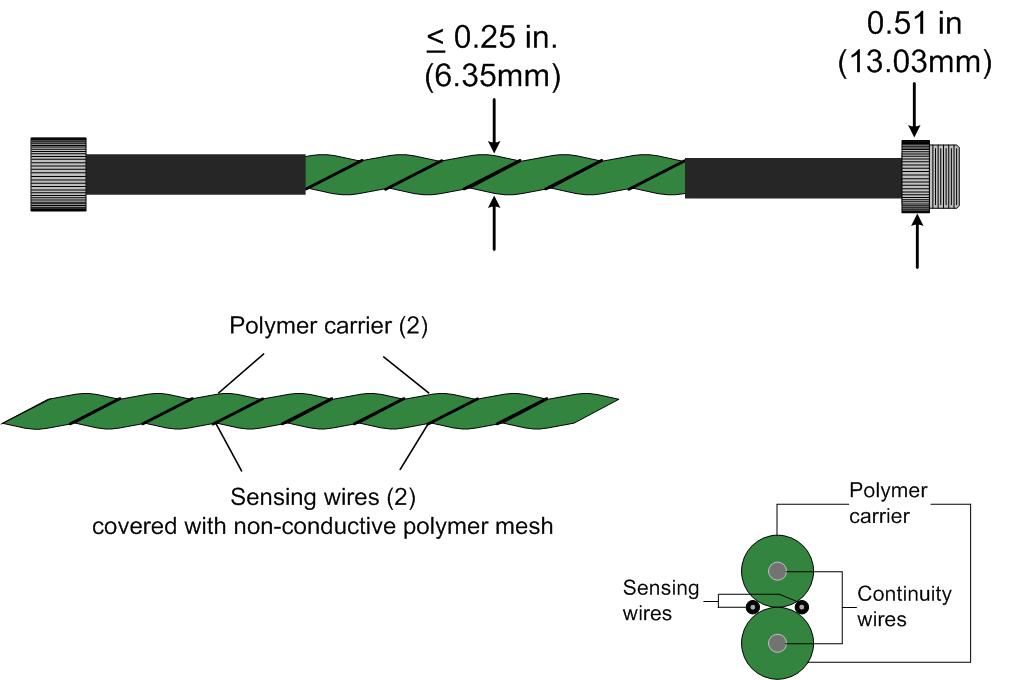

- It’s Strong, Durable, and Reliable – The cable’s abrasion-resistant polymer core increases its strength and durability, and the cable’s sensing wires are enclosed in a non-conductive polymer mesh to help eliminate false alarms.

-

- Robust Connectors Keep it All Together – Cables are assembled with mating metal connectors that will stand up to chemical exposure. Connections between cables and connectors are sealed with a resilient heat shrink tubing to keep chemicals out. The durable mating connectors make it easy to install new systems and to add additional lengths of cable to existing systems.

-

- An Even Faster Reaction Time – Chemical sensing cable reacts even faster than our orange sensing cable. Mind you, the orange sensing cable reacts very quickly to the presence of a leak. The green cable reacts even faster – it’s pretty much instantaneous. Keep in mind there are other factors that contribute to annunciation time, like the type of controller connected to the cable, the cleanliness of the cable, and the operating environment. But we can tell you this: our chemical sensing cable reacts faster than any of our other sensing cables.

Liquid Cooling Protection

Confidently protect your liquid cooled or air cooled data centers with RLE’s leak detection solutions. All SeaHawk leak detection cables support detection of leaks of Propylene Glycol/water mixtures. We support detection blends with up to 35% Propylene Glycol (by weight) including PG15, PG25 and PG35.

Chemical sensing cables are available in a variety of standard and custom lengths:

- 3ft (0.91m) – SC-C-3

- 10ft (3.05m) – SC-C-10

- 17ft (5.18m) – SC-C-17

- 25ft (7.62m) – SC-C-25

- 50ft (15.24m) – SC-C-50

- 100ft (30.48m) – SC-C-100

- Custom Lengths (available upon request) – SC-C-CL

Key Features

- Thermally bonded polymer-coated carrier

- Strong, durable cable

- Highly flexible

- Resists bends and kinks; lies flat after installation

- Quick, simple installation and easy system expansion

- Available in standard and custom lengths with pre-installed end connectors

- Plenum rated, UL listed, and RoHS compliant

SC-C Specifications

Product Characteristics

- Continuity and signal wires: 2 x 18 AWG with fluoropolymer insulation

- Sensing wires: 2 x 27 AWG with conductive fluoroploymer jackets

- Core: Fluoroploymer

- Resistance per Foot: 2.8 ohms

Sheer Strength: 160 lbs. (72.6kg)

Cut Through Resistance: >50 lbs. (>22.7kg) with.005in (0.13mm) blade

Abrasion Resistance: >65 cycles per UL 719

Connector: 4 pin, 0.51 in (13mm) diameter

Chemical Resistance: In accordance with ASTM D543, cable functions normally after seven days’ exposure to the following:

- Fresh deionized water

- Tap water

- Sulfuric acid (98%)

- Sulfuric acid (50%)

- Hydrochloric acid (37%)

- Sodium hydroxide (10%)

- Aqua regia

- Ethylene glycol (60% in DI water)

- Note: Prolonged exposure to concentrated ketones may cause temporary reduction of sensitivity; consult RLE for specific details.

Operating Environment

- Temperature: -40° to 185°F (-40° to 85°C)

- Humidity: 5% to 95% RH, non-condensing

- Altitude: 15,000ft (4,572m) max.

Storage Environment: -40° to 185°F (-40° to 85°C)

Dimensions: Diameter of cable not to exceed 0.24in (6.0mm)

- SC-C-3 : 3ft (0.91m)

- SC-C-10 : 10ft (3.05m)

- SC-C-17 : 17ft (5.18m)

- SC-C-25 : 25ft (7.62m)

- SC-C-50 : 50ft (15.24m)

- SC-C-100 : 100ft (30.48m)

- SC-C-CL-xx : Custom Lengths (available upon request)

Weight: .035 lbs./ft (52 g/m)

Certifications: CE and UL Functional Safety Listing when used in conjunction with RLE controllers; RoHS Compliant; Patent Nos. 8,256,269 and 8,234,910

Product Documentation Links

Technical Resources

Technical Notes

Application Guidelines

Chemical sensing cable is designed to detect the presence of conductive liquid acids and bases, and propylene glycol/water blends with 15% (by weight), or higher (including PG15, PG25 and PG35), and to resist corrosion from these chemicals.

If you are trying to detect non-conductive fluids, like pure de-ionized water, gasoline, diesel fuel, or hydraulic oil, this cable will not work.

Annual Maintenance

Has your cable been installed for a while? You may need to test your system. Depending on your environment, systems should be tested at least once a year. The more hazardous or dirty the environment, the more frequently it should be tested. Refer to our Sensing Cable Care and Maintenance Guidelines and learn how to clean your cables and test your system.