Patented Protection From Even The Smallest Leaks

RLE’s conductive fluid leak detection sensing cable (SC) reliably detects the presence of water leaks and other conductive fluids. It’s one of our hallmark products, and we’ve held the patent for this cable since 2000.

Liquid Cooling Protection

Confidently protect your liquid cooled or air cooled data centers with RLE’s leak detection solutions. All SeaHawk leak detection cables support detection of leaks of Propylene Glycol/water mixtures. We support detection blends with up to 35% Propylene Glycol (by weight) including PG15, PG25 and PG35.

RLE’s conductive fluid sensing cable is:

-

- Durable – manufactured with an abrasion-resistant polymer core, increasing strength and durability. Definitely stands up to foot traffic!

-

- Flexible – easily bends around corners and wraps around pipes, resisting bends and kinks.

-

- Resists False Alarms – engineered to resist contamination and constructed from non-conductive polymers, eliminating false alarms!

-

- Quick to Install – each end of the cable contains mating connectors – this makes it easy to install new systems and to add lengths of cable to existing systems.

-

- Easy to Clean – when it’s visibly dirty, clean it quickly with Dawn dish soap or rubbing alcohol. No special cleaners or cleaning systems required.

-

- Fast Drying – gently wipe the cable dry, and it’s ready to detect the next leak.

Orange fluid leak detection sensing cables are available in a variety of lengths:

- 3ft (0.91m) – SC-3

- 10ft (3.05m) – SC-10

- 17ft (5.18m) – SC-17

- 25ft (7.62m) – SC-25

- 50ft (15.24m) – SC-50

- 100ft (30.48m) – SC-100

- Custom Lengths (available upon request) – SC-CL

With over 20 million feet of leak detection sensing cable installed in systems around the globe, you can’t beat the durability or reliability of our leak detection sensing cables.

How Much Cable Do I Need?

Ready to purchase a SeaHawk system? Download and use our SeaHawk Sensing Cable Length Calculator to make sure you order the right amount of cable.

Key Features

- Durable

- Easy to clean

- Fast drying

- Helps eliminate false alarms

- Able to resist damage from most contaminants

- Highly flexible – resists bends and kinks

- Quick, simple installation and easy system expansion

- Lies flat after installation

- Non-conductive polymer construction

- Thermally bonded polymer-coated carrier

- Plenum rated, UL listed, and RoHS compliant

- Available in standard and custom lengths with pre-installed end connectors

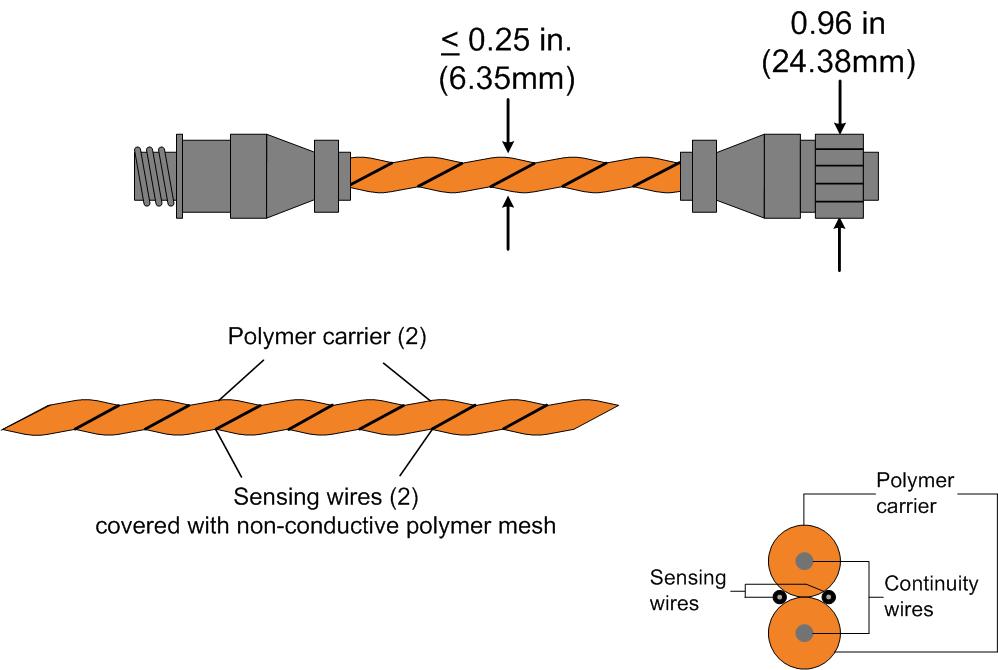

SC Specifications

Plenum Rating: CL2P (UL)

Sheer Strength: >180 lbs. (>81kg)

Cut Through Resistance: >40 lbs. (>18kg) with .005in (0.127mm) blade

Abrasion Resistance: 60 cycles per UL 719

Connector: 4 pin, 0.96in (24.38mm) diameter

Resistance per Foot: 2.8 ohms

Operating Environment

- Temperature: 32° to 167°F (0° to 75°C)

- Humidity: 5% to 95% RH, non-condensing

- Altitude: 15,000ft (4,572m) max.

Storage Environment: -22° to 185°F (-30° to 85°C)

Dimensions: Diameter of cable not to exceed 0.25in (6.35mm)

- SC-3 : 3ft (0.91m)

- SC-10 : 10ft (3.05m)

- SC-17 : 17ft (5.18m)

- SC-25 : 25ft (7.62m)

- SC-50 : 50ft (15.24m)

- SC-100 : 100ft (30.48m)

- SC-CL-xx : Custom Lengths (available upon request)

Weight: .02 lbs./ft (29.74g/m)

Certifications: CE; UL CL2P; RoHS Compliant; Plenum Rated; Patent No. 6,144,209

Product Documentation Links

Technical Resources

Technical Notes

Application Guidelines

Our conductive fluid sensing cable is designed to detect conductive fluids, like water and propylene glycol/water blends with 15% (by weight), or higher (including PG15, PG25 and PG35).

If you are trying to detect non-conductive fluids, like pure de-ionized water, gasoline, diesel fuel, or hydraulic oil, this cable will not work.

Annual Maintenance

Has your cable been installed for a while? You may need to test your system. Depending on your environment, systems should be tested at least once a year. The more hazardous or dirty the environment, the more frequently it should be tested. Refer to our Sensing Cable Care and Maintenance Guidelines and learn how to clean your cables and test your system.